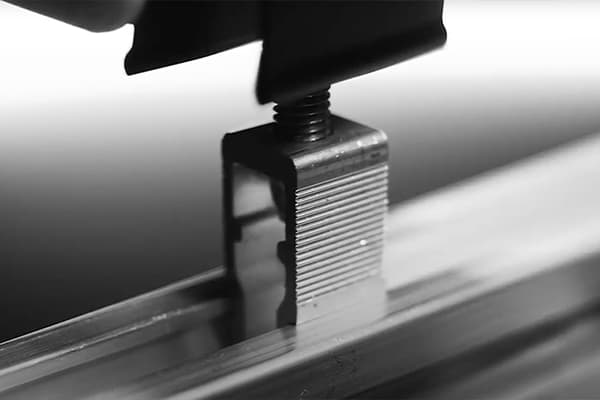

ZERO ROOF PENETRATION

SMART-BALLAST SYSTEMS FOR EVERY STRUCTURE.

Nature never compromises, so neither your flat-roof solar system. Ours are designed and proven to resist anything nature throws at them, from heavy snow and thick ice to extreme heat and strong winds, all while complying with the relevant and appropriate building regulations. Plus, to ensure loads are safe and optimally spread across your building's structure, our expert engineers and next-gen rooftop calculator will calculate the optimal design for your roof's unique shape, size, and slope while safeguarding its integrity.

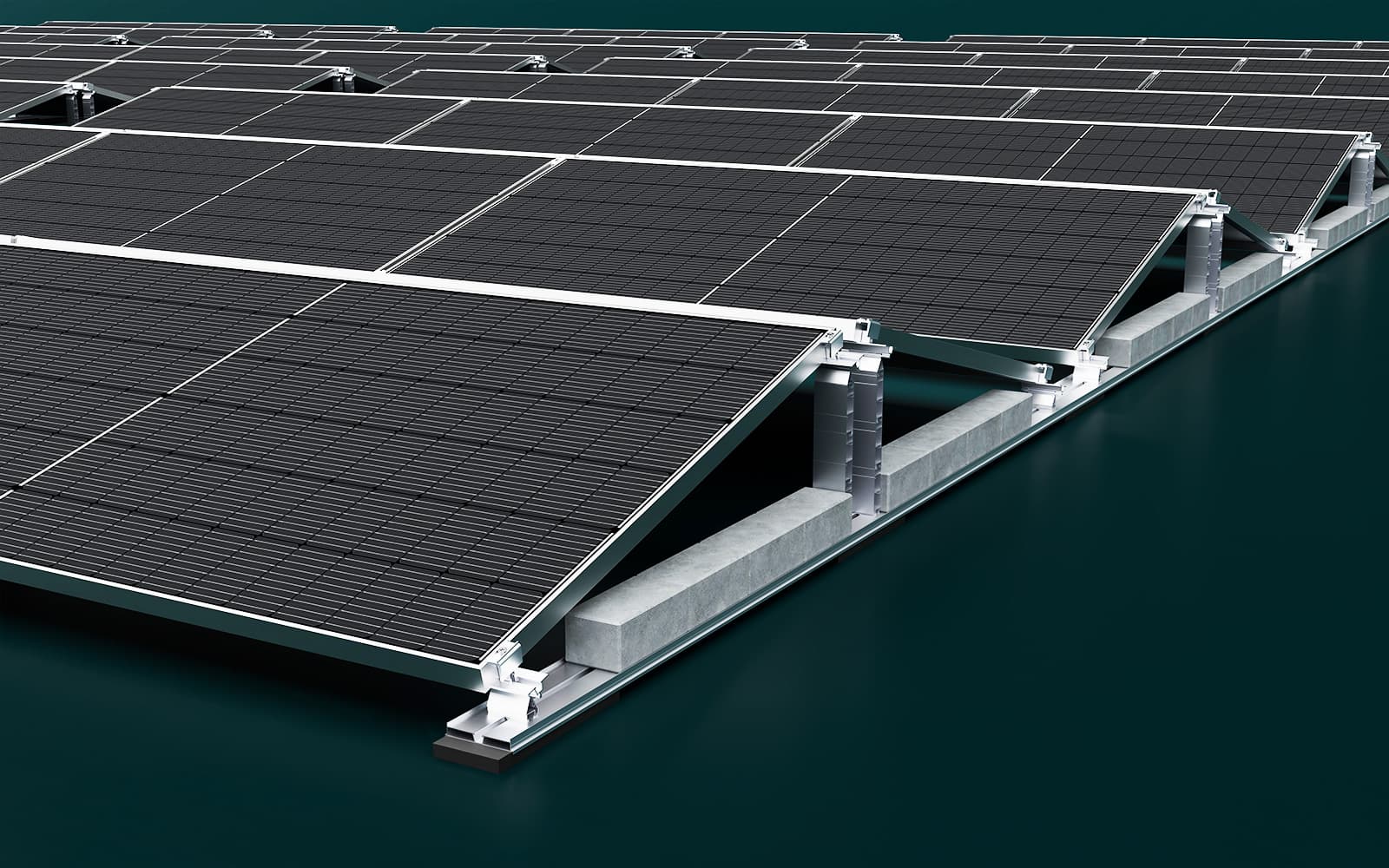

TILTED

FIXGRID.

FixGrid frees you to create a fully-fledged flat-roof system with just a handful of click-in components, with easily achievable angles of 5°, 10° or 15°. With nearly no tools required, assembly is lightning-fast and super-safe, saving you time and labor costs.

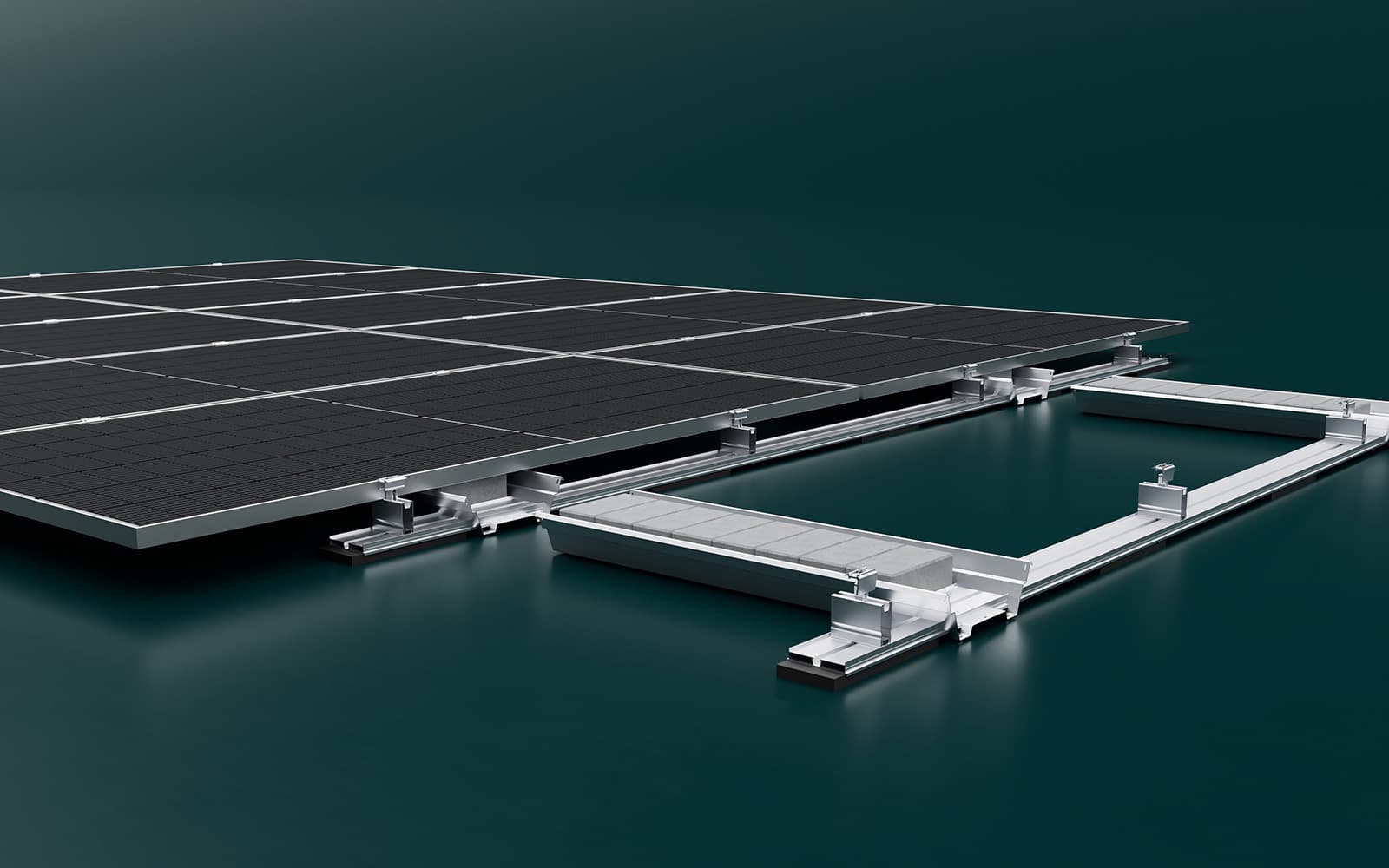

PARALLEL

FLATGRID.

FlatGrid is our strong and straightforward system that enables roof-parallel installations on all flat roofs. Its simple modular principle empowers you to create bespoke configurations with just a few components and even fewer tools.

support

PRE-ASSEMBLED BEAM KITS.

For more unconventional roofs, we’ve developed a suite of support systems so you can install solar without compromising on quality, efficiency or durability.

With small to large beam kits available and accessories that enable you to tailor them to your specific needs, we have everything you need to fit solar on any flat roof.

product catalog

FIND WHAT YOU NEED.

In our rooftop product catalog, you'll find comprehensive overviews of everything you'll ever need to install world-class systems on all pitched and flat roofs. From the smallest screws to complete systems, our catalog's got it all. Take a look.